Country

Thailand

Scope

Rectification and dehydration units to produce ENA and D-ENA Alcohols

Start-up

2023

Main characteristics

Name

Petrogreen Kalasin

Country

Thailand

Scope

Vinasses concentration from cane molasses on forced circulation evaporators

Main characteristics

Name

Country

Argentina

Scope

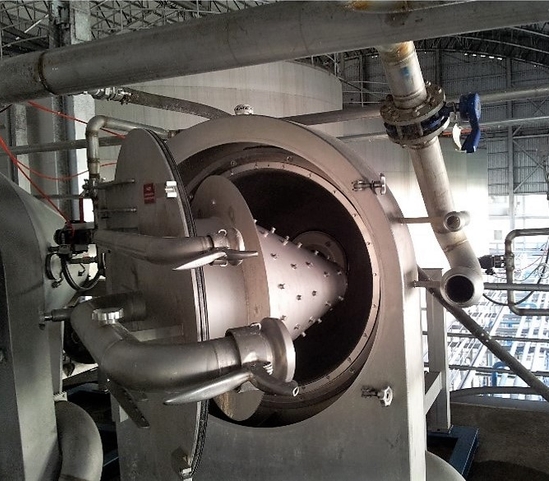

Alcohol dehydration by molecular sieves for biofuel production

Main characteristics

Country

Pakistan

Scope

Multiple effects distillation & rectification from cane molasses for Extra Neutral Ethanol production

Main characteristics

Country

Poland

Scope

Complete process plant for raw alcohol from grain (corn, rye, triticale, barley)

Main characteristics

Name

Country

Thailand

Scope

Complete process plant for Bio Ethanol from Cassava Chips or cane molasses

Main characteristics